What you will learn?

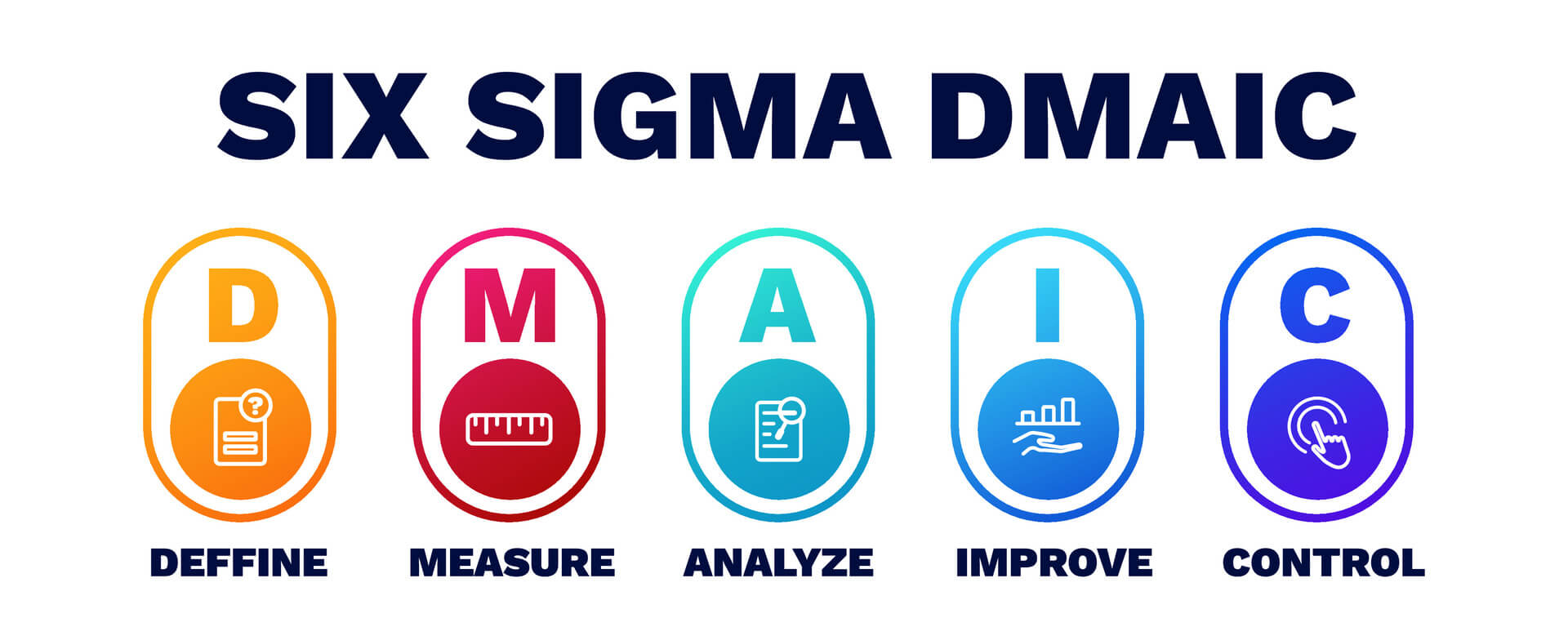

Explain the DMAIC framework and its role in process improvement

Define sigma levels and understand variation and process capability

Identify and interpret customer needs using VOC and CTQ techniques

Construct process maps and analyze workflow inefficiencies

Apply measurement system analysis and SPC tools

Perform root cause analysis and evaluate failure modes

Design and analyze experiments to test process changes

Use advanced statistical tools to guide decision-making

Develop effective control plans for sustained improvement

Integrate Six Sigma with Lean and other improvement methodologies

Target Audience

Quality and process improvement professionals

Operations and manufacturing managers

Project managers and Six Sigma team members

Business analysts and data-driven decision-makers

Professionals preparing for Six Sigma certification (e.g., Yellow Belt or Green Belt)

Anyone interested in systematic approaches to problem-solving and performance improvement

About this course

Participants will gain a deep understanding of key Six Sigma tools such as process mapping, measurement system analysis, statistical process control, root cause analysis, and design of experiments. The course also explores how Six Sigma integrates with other quality initiatives like Lean and the Theory of Constraints to support a culture of continuous improvement.

Real-world case studies and examples provide context for applying Six Sigma principles to real business challenges, from manufacturing and logistics to healthcare, finance, and service industries. Emphasis is placed on aligning process improvements with customer needs using tools like Voice of the Customer (VOC), Critical-to-Quality (CTQ) characteristics, and the Kano model.

Whether you are aiming to improve product quality, reduce costs, or enhance customer satisfaction, this course will equip you with the statistical thinking and structured methodologies necessary to identify problems, measure performance, and implement lasting change.

Requirements

Basic understanding of business processes and workflows

Familiarity with high school-level mathematics and statistics

No prior Six Sigma experience required; suitable for beginners and intermediate learners

Related Courses